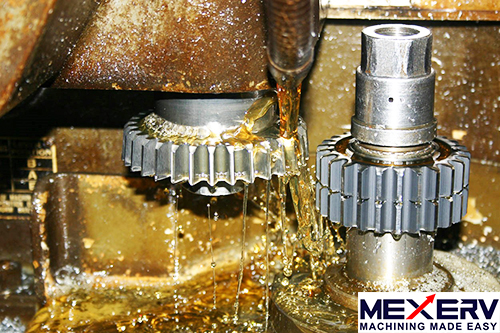

Spur Gear hobbing

Gear Hobbing is a fast and accurate gear manufacturing method. A Hob almost similar to a worm cutter is a rotary tool on which single or multi start threads are cut, with each thread having a shape of an involute tooth. The Gear blank is mounted on the table and the relative motion between the tool and work piece is obtained by the gear train. The Gear blank is moved up to the desired depth and the Hob will be moved in a direction axial to the job.

This list outlines types of hobs in conventional use

- Roller chain sprocket hobs

- Worm wheel hobs

- Spline hobs

- Chamfer hobs

- Spur and helical gear hobs

- Straight side spline hobs

- Involute spline hobs

- Serration hobs

- Semi topping gear hobs

Spur gears or straight-cut gears are the simplest types of gears available. They are made up of a cylinder or disk with the teeth projecting radially. Spur gears will be able to mesh together correctly only if fitted to parallel shafts. No axial thrust will be created by the tooth loads. These gears work seamlessly at low or moderate speeds but tend to be noisy at high speeds. Spur gear can technically be classified into two pressure angles, 20° being the current industry standard for manufacture and 14½° being the old standard.